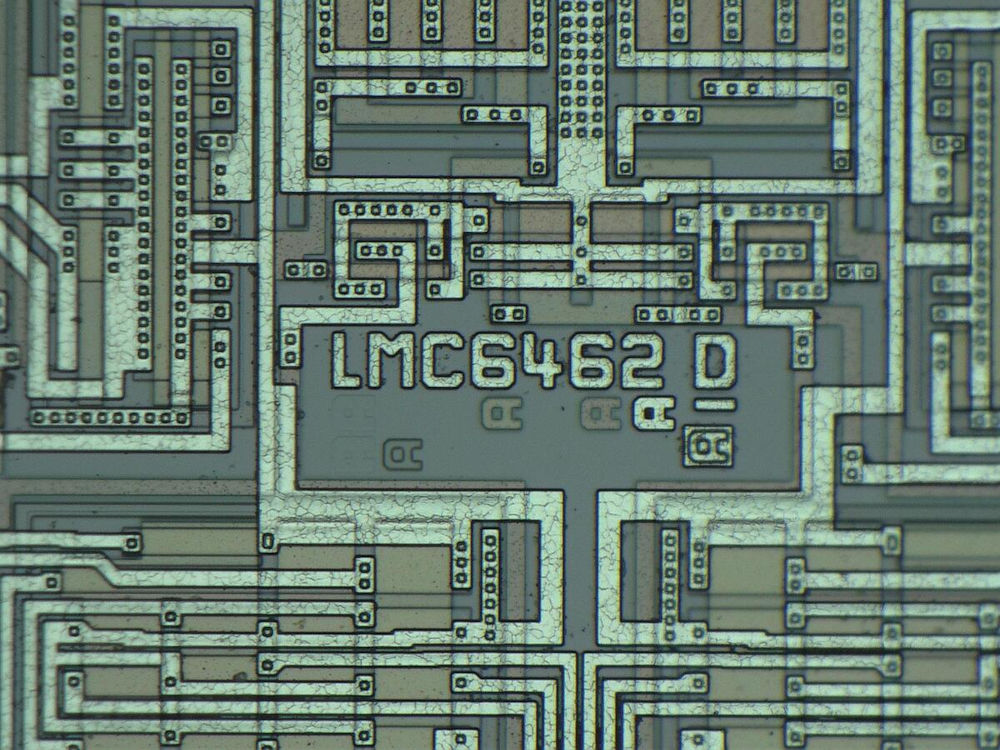

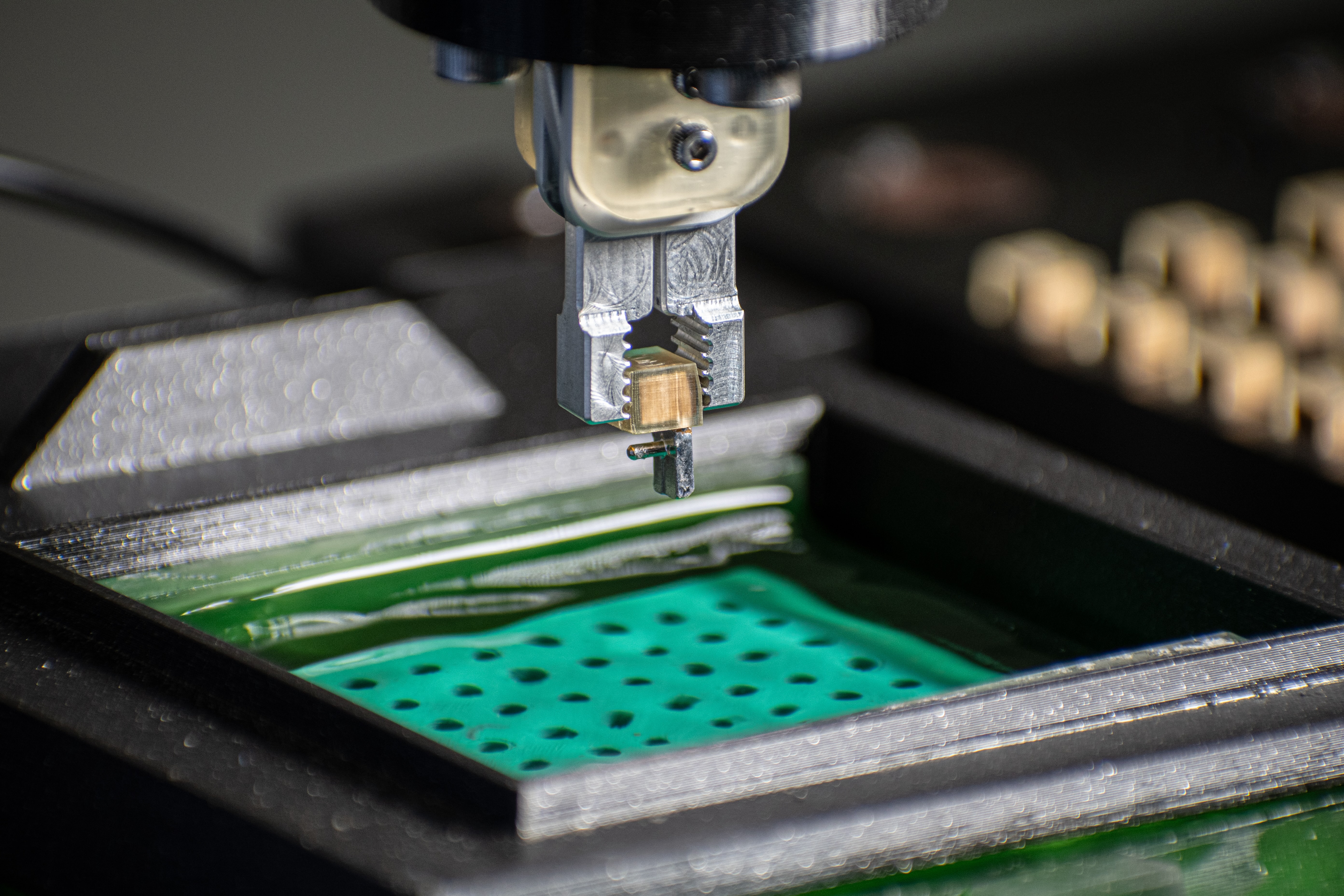

Our Services

We are strategically located throughout the world.

View More

Florida

Malaysia

California

Shenzhen

Netherlands

Hong Kong

Taiwan

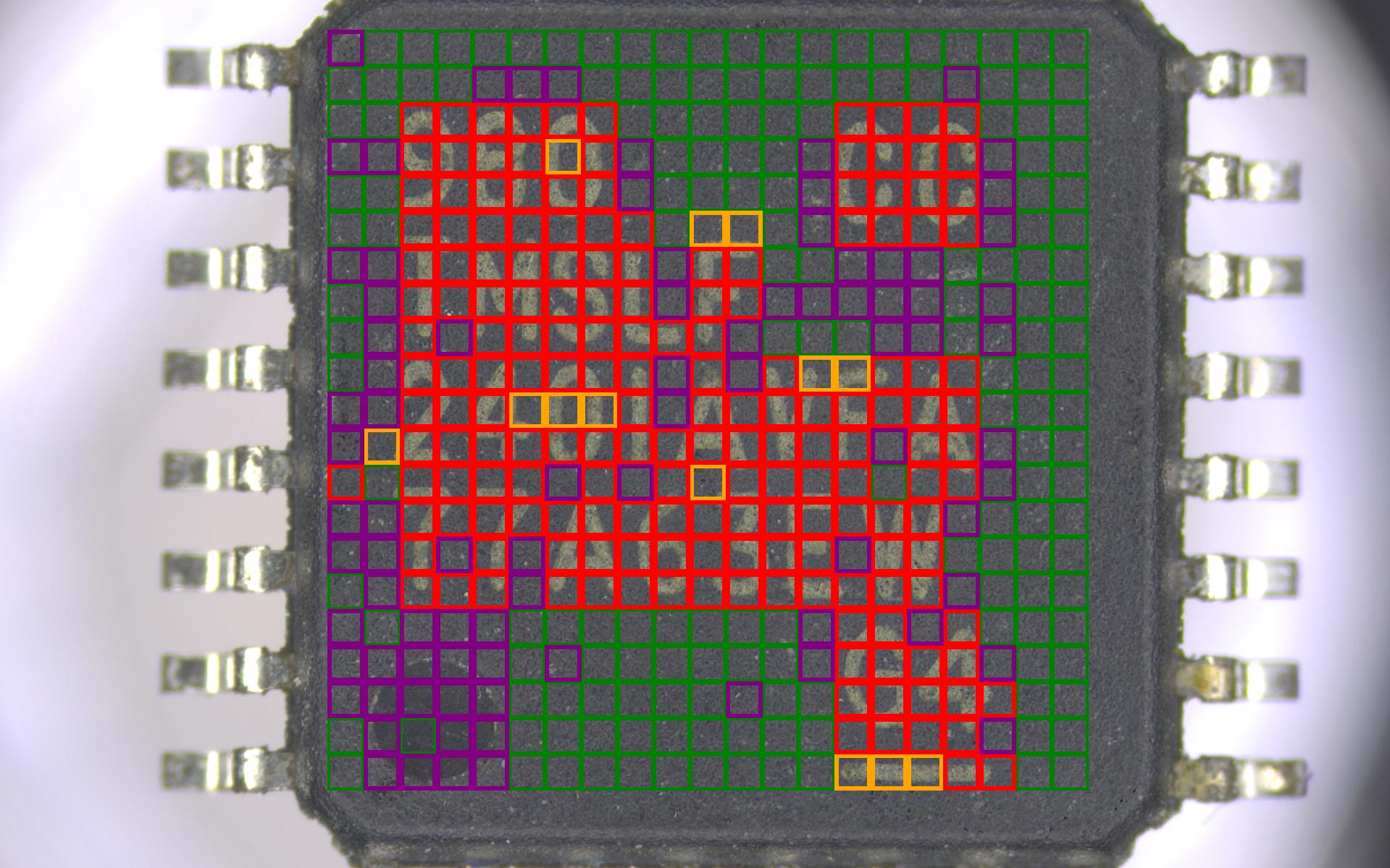

Level 3

Level 2

Level 1

ISO 17025, AS6171, AS6081

ISO 17025, AS6171, AS6081 DLA Lab Suitability

DLA Lab Suitability ITAR

ITAR