1. "Lean Management Principles and Practices" - Lean Enterprise Institute

2. "ISO 9001: Quality Management Systems" - International Organization for Standardization

3. "AS 9100: Aerospace Quality Management System" - SAE International

Introduction to Lean Management in Laboratory Testing

Value Stream Analysis for Standardized Processes

Integration of ISO Standards for Quality Management

Comprehensive Procedures and Systems for Efficiency

Cultivating a Culture of Continuous Improvement

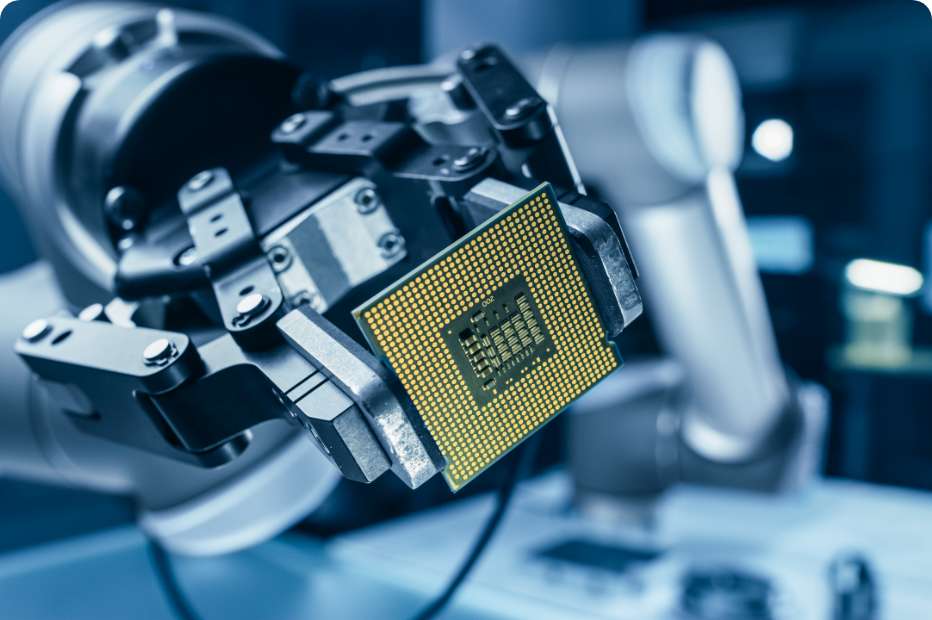

In the realm of laboratory testing, efficiency and quality are paramount. Lean management principles offer a pathway to achieve both simultaneously. At Global Electronics Testing Services (GETS), we embrace lean production management to optimize our operations. By leveraging unique patented software, hardware, analytical testing, and tracking methods, we standardize testing processes and reduce testing times.

Central to our approach is value stream analysis. This method allows us to scrutinize every step of our processes, ensuring they are standardized for efficiency and quality. Through value stream analysis, we identify and eliminate waste while aligning information and material flow. This optimization ensures that each test is conducted with precision and within a predictable timeframe.

GETS is committed to maintaining the highest standards of quality. To this end, we integrate ISO 9001, AS 9100, and ISO 17025 standards into our operations. These standards serve as frameworks for quality management, guiding us in minimizing errors and maximizing customer satisfaction. By adhering to ISO standards, we elevate our quality management practices and ensure consistency across all testing procedures.

Our commitment to efficiency is reflected in our comprehensive procedures and systems. We leverage advanced IT systems and real-time order tracking to streamline our operations. These systems enable us to visualize order allocation and completion, ensuring that each order is processed with minimal delay. By optimizing resource coordination and utilization, we maintain high efficiency levels across all departments.

At GETS, we understand that continuous improvement is essential for long-term success. We invest in employee training and ongoing maintenance of our IT systems to facilitate this culture of improvement. By empowering our team members to identify areas for enhancement and providing them with the necessary tools and support, we ensure that our laboratory remains adaptable and responsive to evolving needs and markets.