January 2025 Testing Summary

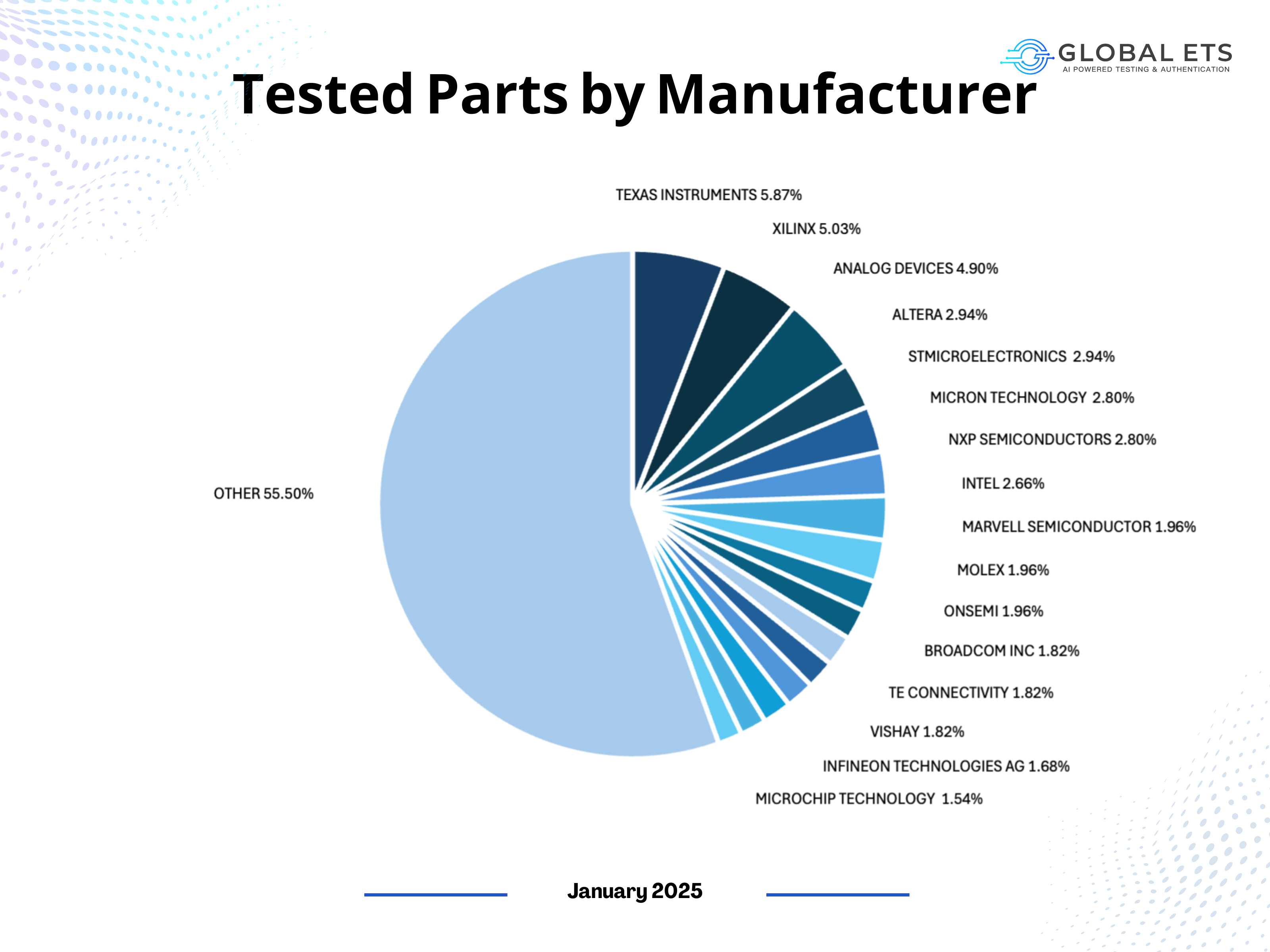

Types of Parts Tested per Manufacturer

Introduction

At Global ETS, we will continue to use data to mitigate risks and provide REAL data in the electronic component industry. As a partner to OEMs, CMs, and industry professionals, we consistently evaluate testing results to provide helpful insights. With another month of testing complete, let's explore what January’s findings reveal about the current landscape.

Types of Parts Tested per Manufacturer

Our lab continues to see a steady influx of components from the industry's top manufacturers. Texas Instruments led the way in January, accounting for 5.87% of all parts tested. Xilinx followed closely behind at 5.03%, reclaiming a higher spot after a shift in rankings the previous month. Analog Devices rounded out the top three at 4.90%, demonstrating its continued relevance in the market. These fluctuations in manufacturer presence offer an intriguing glimpse into general demand.

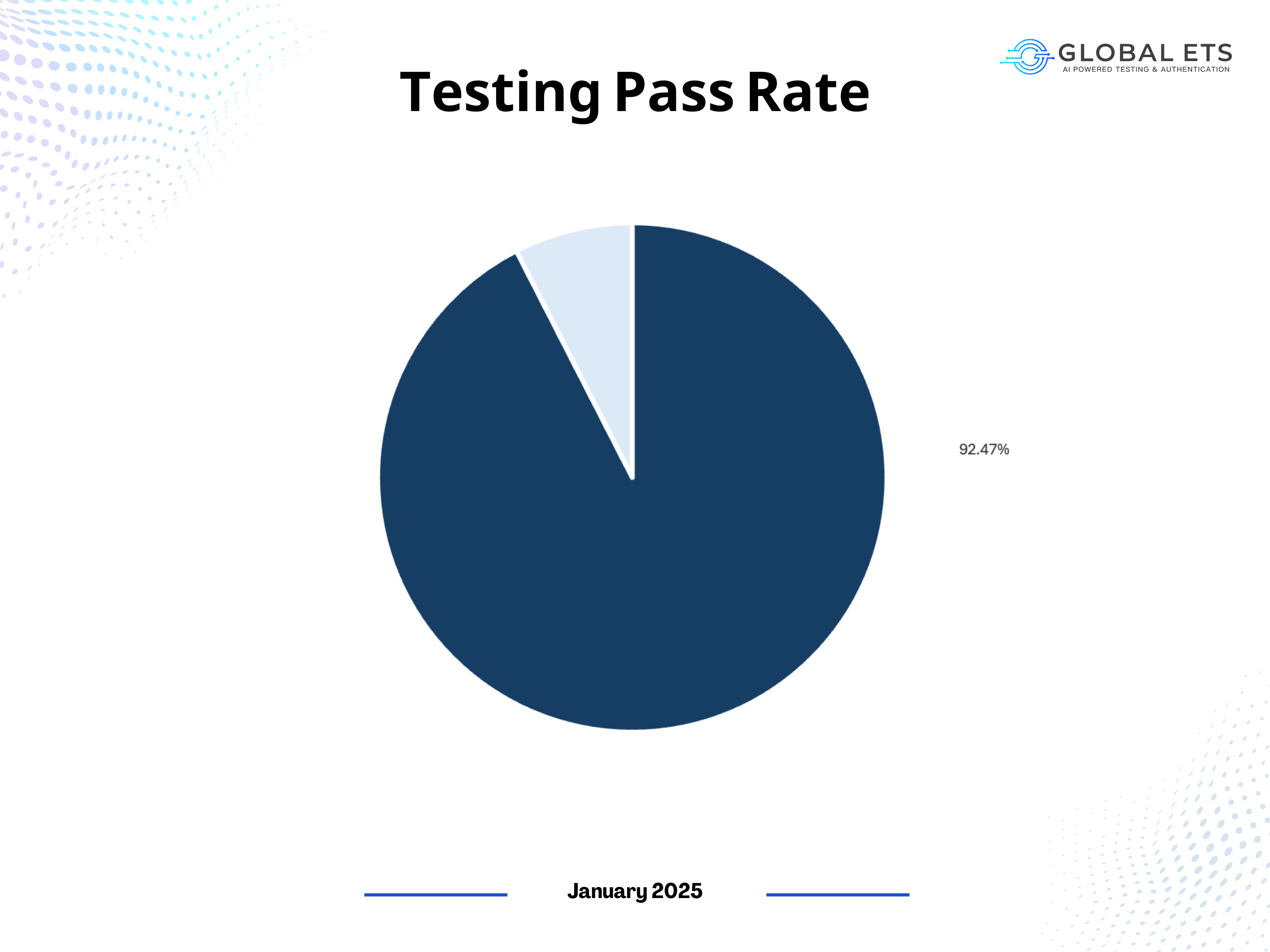

Pass Rates of Components

Our data shows an overall pass rate of 92.47% for January, slightly higher than December’s 92.11%. Most components meet their specified quality and authenticity standards, however, the 7.53% failure rate underscores the ongoing risk of counterfeit parts, defects, or inconsistencies. Identifying these issues during testing helps companies avoid costly errors and ensures functioning systems.

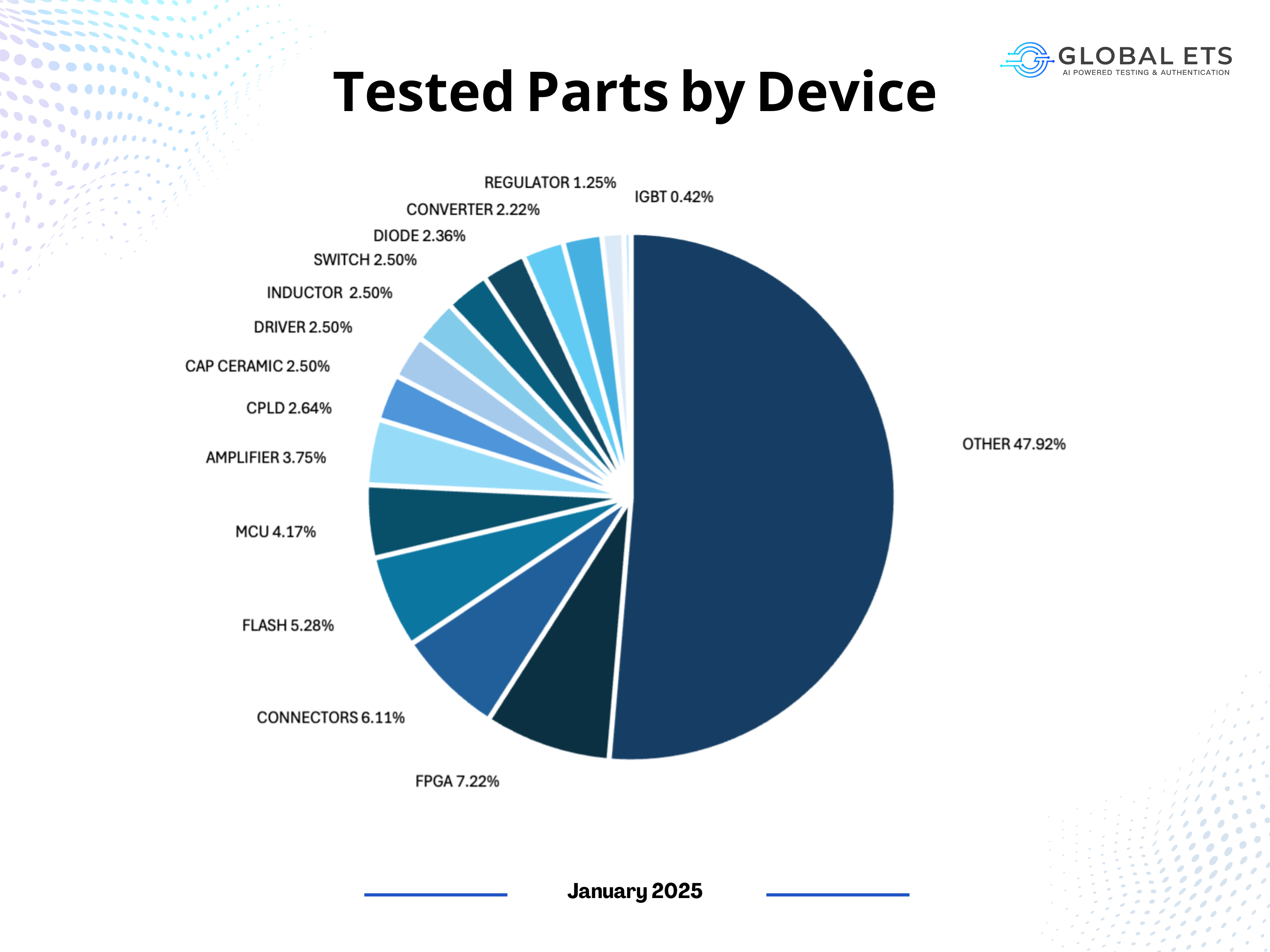

Parts Tested by Device Type

In January, we observed a steady stream of FPGAs (7.22%), connectors (6.11%), flash memory (5.28%), microcontrollers (4.17%), and amplifiers (3.75%) passing through our lab. FPGAs remained in high demand, supporting applications that require reconfigurable computing, while connectors played a crucial role in ensuring seamless electrical connections. Flash memory continued to be a staple in modern storage solutions, and microcontrollers were seen more frequently in our testing cycles. Amplifiers, critical for producing clear and accurate signals, rounded out the list of frequently tested components. The diversity of parts tested highlights the intricate ecosystem of electronics, reinforcing the need for rigorous quality control at every stage.

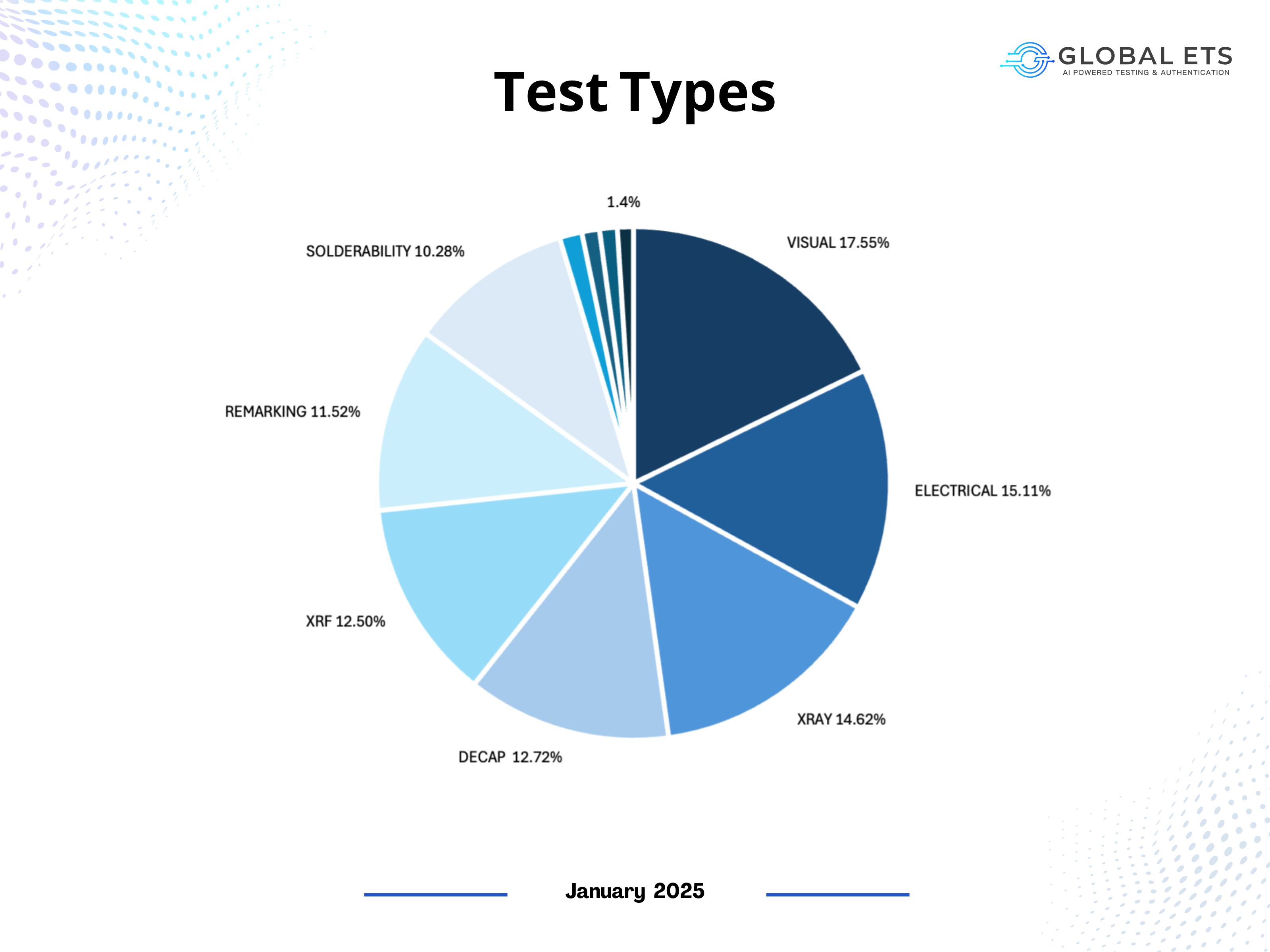

Types of Tests Performed

Ensuring the authenticity and functionality of components requires running multiple different tests. Visual inspection remained the most commonly performed test (17.55%), serving as the first line of defense in identifying defects and anomalies. Electrical testing followed closely behind (15.11%), with X-ray analysis taking the third spot (14.62%). Beyond these primary methods, other specialized techniques, such as decapsulation (12.72%) and XRF (12.50%), play a key role in confirming die authenticity and material composition, rounding out the top 5 for this month. By combining these methods, we help companies mitigate risk and maintain the highest standards of quality.

Conclusion

At Global ETS, we take pride in helping companies build their products with high-quality, authentic electronic components. Our data highlights the importance of ongoing testing in navigating the complexities of the global supply chain.

For more information about how Global ETS can assist with your component testing and authentication needs, visit our website at www.gets-usa.com or contact us at sales@gets-usa.com.

ISO 17025, AS6171, AS6081

ISO 17025, AS6171, AS6081 DLA Lab Suitability

DLA Lab Suitability ITAR

ITAR