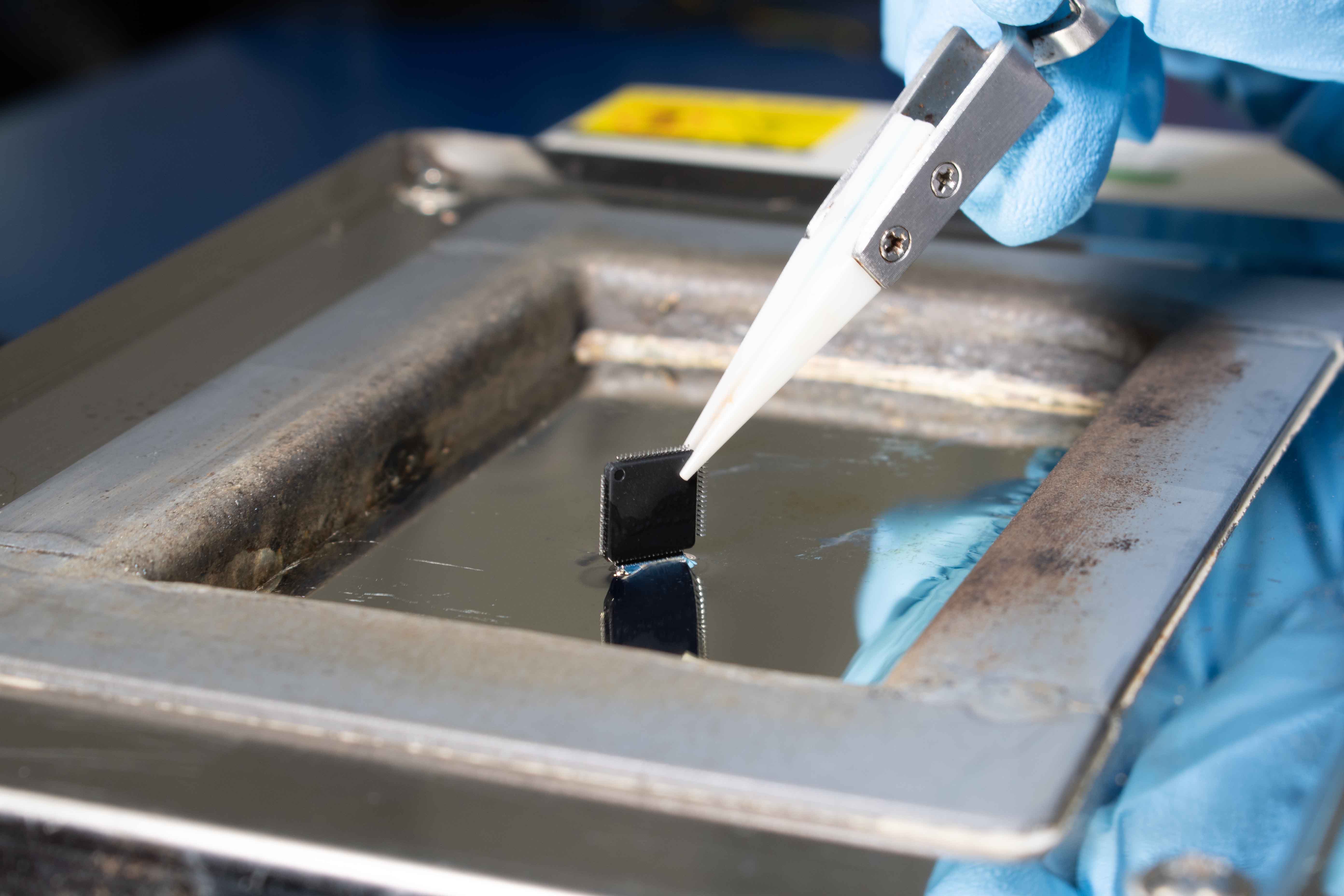

Manual Tinning

Manual tinning procedures, characterized by the submersion of components into a tin bath, are susceptible to a range of human errors. These errors include inconsistencies in crucial factors such as dip time, dip angle, processing speeds, and overall precision. The manual tinning process is labor-intensive, requiring a high level of skill and experience from operators to maintain accuracy.

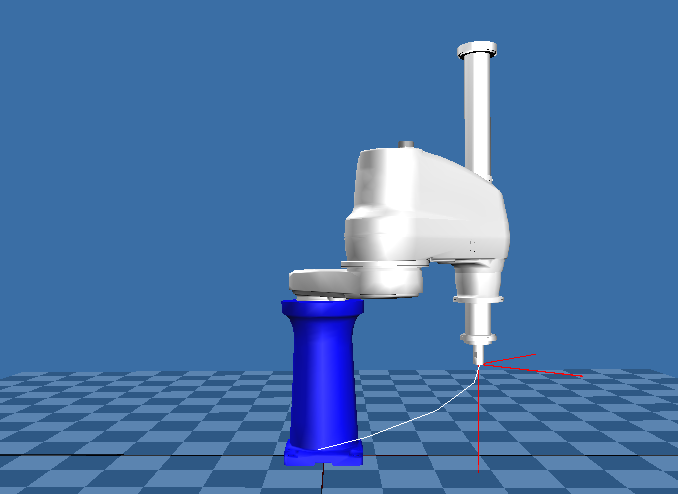

Automated Tinning machine

Our Automated Tinning Robot represents the advanced engineering capabilities here at Global ETS. Carefully designed and calibrated by our engineers, this robotic re-tinning system ensures exceptional accuracy in the re-tinning process while still following industry standards.

ISO 17025, AS6171, AS6081

ISO 17025, AS6171, AS6081 DLA Lab Suitability

DLA Lab Suitability ITAR

ITAR