October Testing Summary

Types of Parts Tested per Manufacturer

Introduction

Global ETS continues to lead the electronic component testing industry worldwide. By leveraging data analytics from our network of locations, we provide insights into industry trends and address the critical issue of counterfeiting. Our long-standing partnerships with OEMs and CMs ensure that the data we share is grounded in practical expertise and thorough testing.

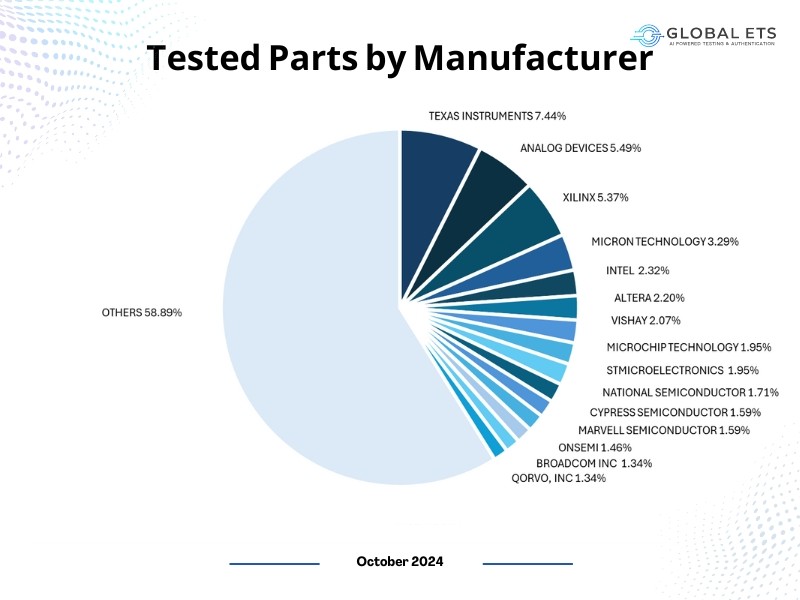

Types of Parts Tested per Manufacturer

In November, we observed a shift in the types of parts tested per manufacturer. The top three manufacturers for the month are Texas Instruments, Intel, and Microchip, accounting for approximately 20% of all parts tested. This highlights the growing demand for microcontrollers and analog components, driven by the automotive and industrial automation sectors. Additionally, the presence of these manufacturers in the top ranks may indicate an increased focus on testing high-performance parts to prevent counterfeit risks.

Pass Rates of Components

The overall pass rate for November increased slightly, reaching 95%. This improvement reflects continued efforts from suppliers to enhance quality control and reduce counterfeit infiltration in the supply chain. A higher pass rate means fewer production delays and better reliability, which are critical for meeting the demands of high-stakes industries such as aerospace and healthcare.

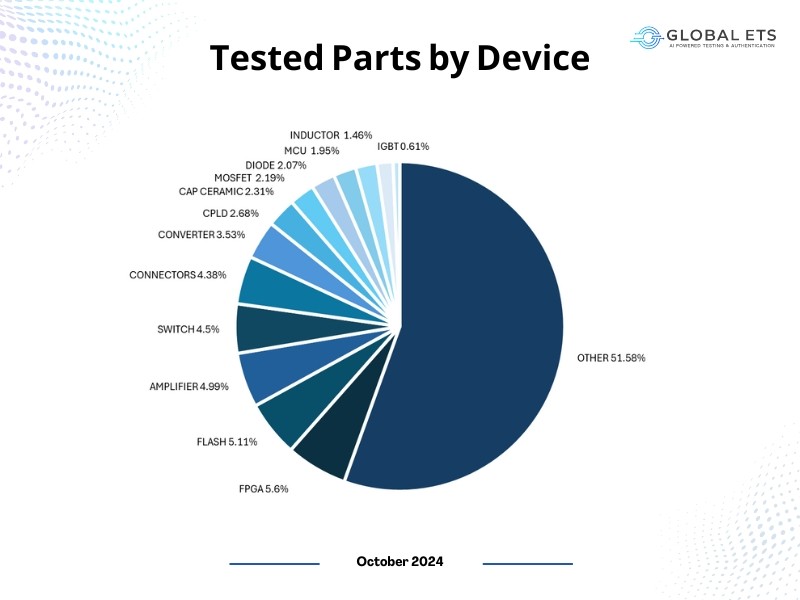

Parts Tested by Device Type

This month, the top five device types tested include FPGAs, power modules, sensors, flash memory, and MOSFETs. The surge in power modules and MOSFETs aligns with the growing adoption of electric vehicles and renewable energy systems. Similarly, the high testing volume of sensors and FPGAs points to advancements in IoT and AI-driven applications, which require precise and reliable components for seamless operation.

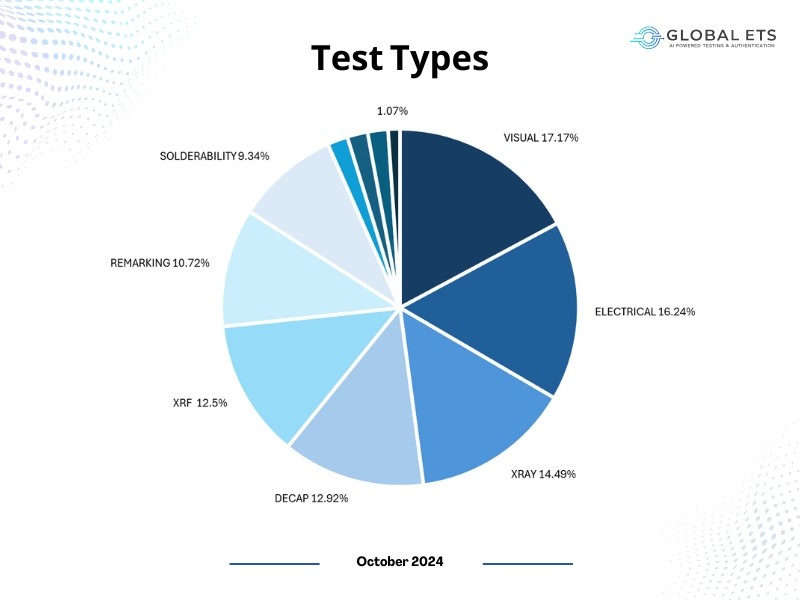

Types of Tests Performed

Visual testing continues to dominate as our most frequently performed method, followed closely by electrical and X-ray testing. Together, these three testing methods account for 49% of the total tests performed this month. The effectiveness of these tests lies in their ability to detect tampering, defects, and counterfeit indicators, ensuring the components meet the highest quality standards before entering the supply chain.

Conclusion

At Global ETS, our mission is to ensure that every component entering the supply chain is authentic and reliable. By analyzing trends and adapting to industry needs, we remain a trusted partner for manufacturers and suppliers. As the landscape continues to evolve, we aim to provide insights that help secure the future of the electronics industry.

For more information about how Global ETS can assist with your component testing and authentication needs, visit our website at www.gets-usa.com or contact us at sales@gets-usa.com.

ISO 17025, AS6171, AS6081

ISO 17025, AS6171, AS6081 DLA Lab Suitability

DLA Lab Suitability ITAR

ITAR