Traditional Method

Manual Programming

Traditional IC programming is a time-consuming, multi-step process requiring specialized adapters and costly tools, often leading to production bottlenecks and reduced flexibility.

New Method

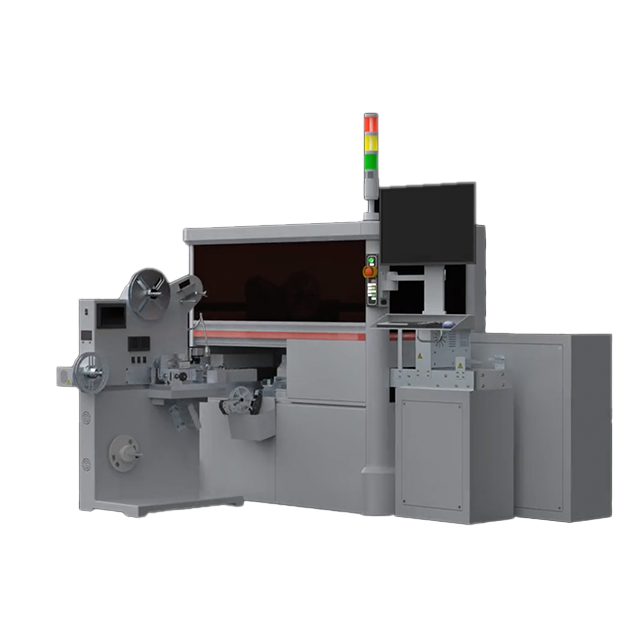

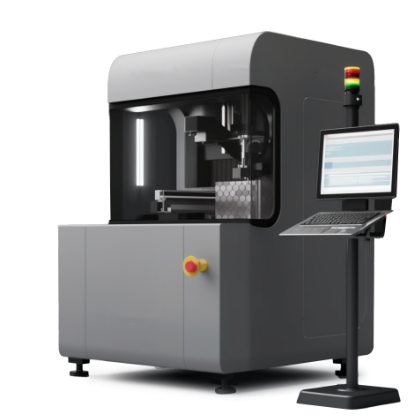

Automated Electrical Testing System

Our new Automated Electrical Testing System delivers up to 2500 units per hour, uses dual nozzles for simultaneous pick-and-place, and programs up to 32 chips with exceptional accuracy and minimal noise. Unlike traditional IC programming methods, this machine boosts productivity, reduces error rates, and minimizes production issues.

Efficient Production

The Automated Electrical Testing System can simultaneously program 32 chips across four universal programmers, achieving an efficiency of up to 2500 units per hour. Optimal throughput and resource efficiency make this system perfect for large-scale electronic product production.

Dual Nozzle Technology

Featuring a dual nozzle system, the Automated Electrical Testing System delivers high-speed, precise pick-and-place operations with minimal noise output. This enhances overall performance and can accommodate IC packages from 1.2 x 1.1 mm to 40 x 40 mm.

Integration and Traceability

The Automated Electrical Testing System connects directly to a manufacturing execution system (MES), providing full control and traceability throughout the production process.

ISO 17025, AS6171, AS6081

ISO 17025, AS6171, AS6081 DLA Lab Suitability

DLA Lab Suitability ITAR

ITAR