Traditional Method

Optical Microscope

The potential for inaccuracies, the risk of damage, the labor-intensive nature, and the absence of real-time data contribute to inefficiencies in workflow.

New Method

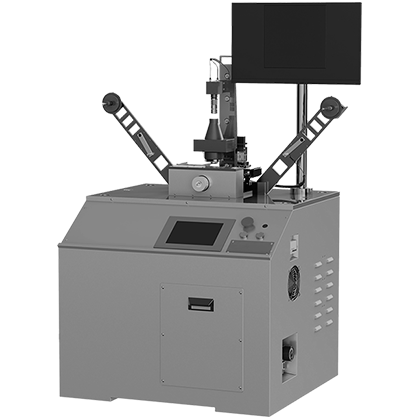

AOI System

This device empowers users to accurately identify bent leads, pin1 indicator, and abnormal markings within the reel in real-time, significantly reducing the inspection time. This capability effectively minimizes the risk of parts getting damaged during the Surface Mount Technology (SMT) process, ensuring uninterrupted operations and maintaining a high standard of precision.

Model template creation

Quality visual inspections of AOI machines guarantee that products meet the required specifications for function, reliability, and safety requirements. Simply by setting parts orientation, marking appearance, and mechanical specification based on a golden sample.

Marking inspection

Surface Mount Technology has no room for error when it comes to safety, reliability, and manufacturing efficiency; every component mounts on the board must be accurate and at right orientation. Investing in advanced inspections is not only cost-efficient but also ruled out possibility of expensive recall and accidental compensations due to suspect or irrelevant parts.

Leads inspection

The rigidness and complexity of electronic products lifespans, and tight industry restriction do not leave much room for human errors. With the advanced inspections, any bent leads, missing leads or leads coplanarity can be triggered once dimensions fall out of range from manufacture requirements.

ISO 17025, AS6171, AS6081

ISO 17025, AS6171, AS6081 DLA Lab Suitability

DLA Lab Suitability ITAR

ITAR